DIY solar air heating collectors for space heating can offer the best bang for the buck of any solar project I know. These collectors are simple and cheap to build and can have payback periods as short as one season! They offer a particularly attractive option to the Do-It-Yourselfer -- commercial solar air heating collectors with prices pushing $2000 can literally be built as DIY projects for $200!

|

| Side by side testing of two solar air heating collector designs |

One of the biggest questions facing someone wanting to build one of these collectors is to decide which of the many collector designs out there to build. Its fairly easy to look at the designs and evaluate construction difficulty and cost, but the big missing factor is the efficiency of each design.

Scott and I have been doing a winter long set of testing on some of the common DIY solar air heating collector designs to try and get a handle on comparative performance. We have adopted the approach of building full size prototypes of each collector design. These prototypes are identical except for the absorber and inlet and outlet details that make a design unique. We then test two of the collectors side by side such they both see the same sun, ambient temperature, wind, etc. In these tests, one of the two collectors is always the standard baseline design, so each new collector is being compared to the same baseline design. This procedure makes it much easier to get a true comparison of the various designs.

|

| Performance plot for side by side collector performance test |

|

| Blower and airflow measuring setup for collector testing. |

I've pasted in the summary of results for the winter of 2010 - 2011 just below. If you want a detailed description of each collector design and the testing that was done on it,

see the full report...

As it turns out, one of the simplest collector designs did very well, so you can have simplicity and high performance with the same design.

-------------------------------------------------------

Summary of Tentative Results for Winter of 2010 - 2011 Tests:

This is a tentative ranking of the collectors from best overall down based on the testing that was done.

I ranked this the best because it has a great combination of high performance, low cost, and is a very easy build.

This collector also has a low pressure drop which means a smaller (maybe quieter and cheaper) fan can be used to drive it.

The screen collector surprised both Scott and I -- we initially included it because it is easy to build, and the thinking was that even it is not up to the performance of some of the others it might be a winner in low cost and easy build.

As it turns out, none of the other collectors did better in performance.

Performance rating: base -- this was the best performer and is the base for performance drops shown below for the other collectors.

In the performance area, this collector was basically tied with the screen collector, and there may be further optimizations that could be done to improve its performance from what was tested.

Its a relatively simple build, but harder and more expensive than the screen collector.

The pressure drop through this collector is low (which is good).

Performance rating: About equal to the base screen collector

While this collector did not perform as well as the screen collector, I would hold off on judging performance until a more optimized one can be tested.

On the negative side, its the most expensive of the collectors listed here to build, and its not clear (to me) exactly what needs to be done to the design to get a more even flow distribution.

The pressure drop through the collector is low (which is good).

The downspout collector appears to be well suited to long narrow collectors that might be difficult to do with a screen or soffit collector?

Performance rating: In my test, 40 to 50% off the screen collector, but my downspout collector was not optimized, and can improve.

This is the old standby design that has been popular for many years.

The version that we tested turned out to have performance that was not as good as the screen collector.

The backpass collector had the highest pressure drop of any of the tested collectors (which is bad).

There are a lot of variations possible on this design, and its certainly possible that other versions would do better.

Performance rating: About 10 to 20% off the screen collector. Optimization of the baffles would improve the backpass collector.

This one certainly is the winner on ease of build and cost -- its literally an empty black box with air blown through it.

The performance was poor.

Testing it sort of answers the question I get a lot saying "Why not just build and empty black box and blow air through it? "

The answer is that you can do this, and it works, but you are giving up a lot of performance compared to other designs.

It may be possible to start with an empty box design, and figure out a way to add good baffling that would get a more even distribution of air over the full absorber, and make this design much more competitive. On the other hand, you could start with an empty box and add a couple layers of screen :)

Performance rating: About 50% to 60% off the screen collector -- that is, adding two layers of window screen roughly doubles the heat output!

These results agree with Scott's tests with the exception of the downspout collector, which Scott did not have a chance to do a side by side test on. I think that it is significant that we were able repeat each others results with completely independent test setups.

Things to bear in mind in interpreting the performance results:

-

None of these collector designs has been optimized for best performance. They can all likely benefit from design refinements -- some likely more than others.

-

Coming up with a good method to measure airflow accurately in order to insure that the two collectors being tested side by side were getting the same airflow proved to be very difficult. The methods used included: time to inflate a large bag of known size, velocity measurements with a Kestrel turbine style anemometer, using the flow generated voltage of PC fans in the collector flow, a hot wire anemometer, and pitot tubes to measure. The methods changed from test to test, and the fact that some of these methods have an unknown amount of error introduces some uncertainty into the results.

-

The original plan was to identify one collector design as the baseline, and to include this collector as one of the two collectors in each side by side test -- this way each new design was always being compared to the same baseline design. The original choice for the base collector was the backpass collector. But, after testing the screen collector and seeing how well it did with such a simple and easy to build design, we decided to change the baseline to the screen collector -- this makes it easier for anyone who wants go join in this testing to do so. But, this again introduced a bit of uncertainty in the test program.

-

The weather was different for each test, so basically each pair of collectors was tested on a somewhat different part of its efficiency curve. This was one of the main reasons for always including the baseline collector in each test. I did attempt to do each test on a clear day with outside temperatures that are typical of real winter conditions (the downspout collector test was the one exception with a fairly high 49F ambient temperature).

One final note on the testing is that as a sort of check on the whole process, I built a 2nd screen collector that is the same as the first one. I tested the two screen collectors against each other in a side by side test. I used the same setup, blowers, flow measurement techniques as are described above for all the other tests. So, this is a check on the whole side by side method of testing and on the instrumentation. The difference in heat output between the two was 3%. Of course, if both collectors were completely identical and the instrumentation, flow rate setup, ... were exactly the same for both the heat output difference would have been 0%. I guess that one message here is don't be looking at differences of 2 or 3% as significant -- these kinds of differences arise from small differences and construction and measuring techniques.

I'm probably going to do more testing next winter with an eye toward repeating some of these tests with a better airflow measuring setup, and then (hopefully) get into some changes to improve the design on some of them.

I'd very much like to hear from anyone who has ideas on what was done this last winter and what might be done next winter. Any feedback on whether any of this was helpful in deciding what kind of air collector to build and/or deciding to build one at all.

Gary...

Gary

This is Tim's setup -- it uses a chimney that is not in use anymore to channel the air down to the kitchen. A homemade differential controller decides when to turn the blowers on.

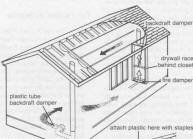

This is Tim's setup -- it uses a chimney that is not in use anymore to channel the air down to the kitchen. A homemade differential controller decides when to turn the blowers on. The picture to the left is the "Black Roof" solar heating scheme. This scheme basically harvests attic heat for space heating with just a few simple components and a blower. It is said to be effective in cold climates that get quite a bit of sun -- eg Colorado.

The picture to the left is the "Black Roof" solar heating scheme. This scheme basically harvests attic heat for space heating with just a few simple components and a blower. It is said to be effective in cold climates that get quite a bit of sun -- eg Colorado. There have been a number of schemes to use the attic heat to preheat domestic water. This is a recently announced commercial offering that uses PEX tubes installed in the attic vent system to harvest heat.

There have been a number of schemes to use the attic heat to preheat domestic water. This is a recently announced commercial offering that uses PEX tubes installed in the attic vent system to harvest heat.